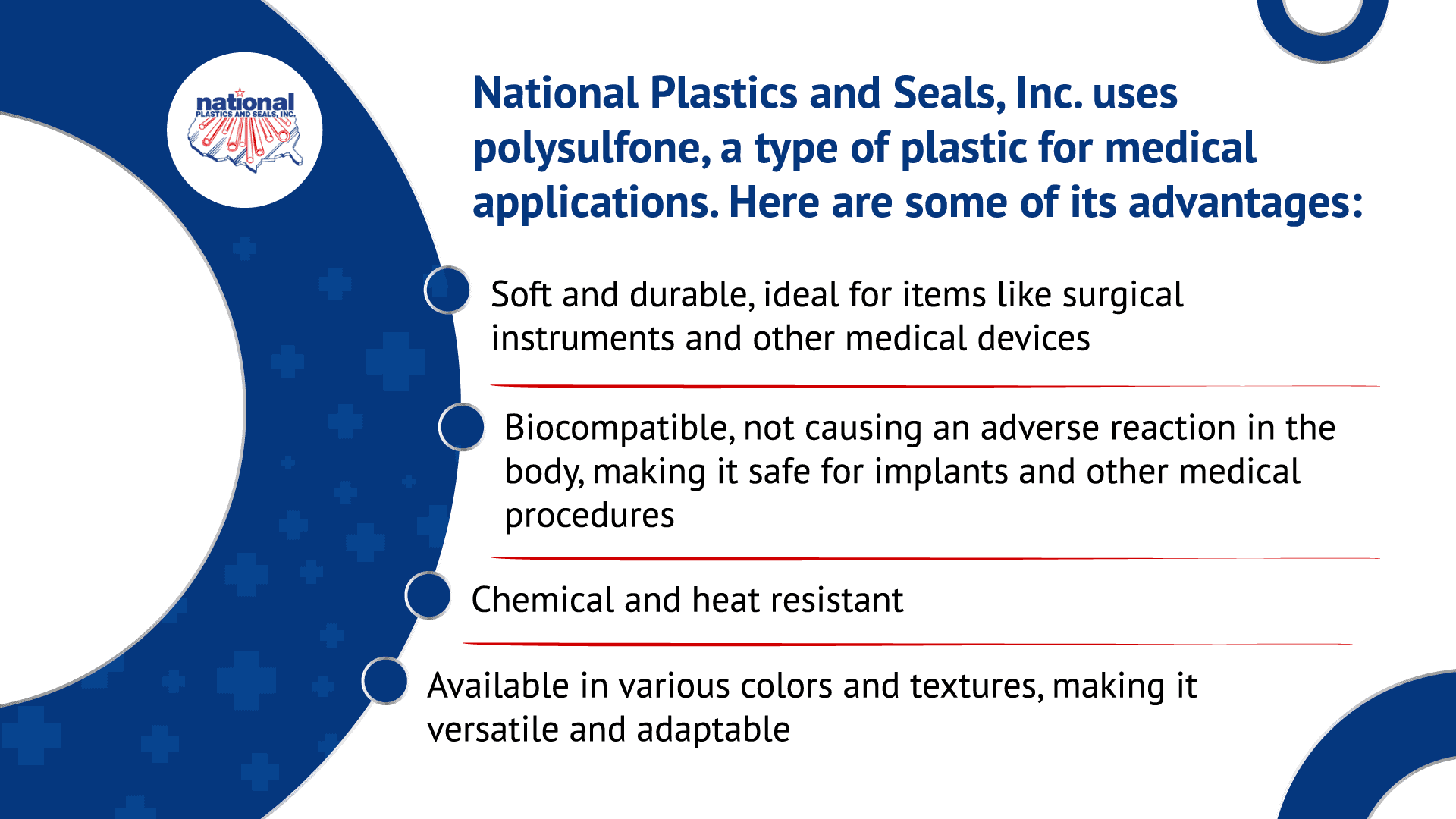

National Plastics and Seals is a top-tier provider of precision-machined plastic parts for the medical industry. One of our specializations is polysulfone material, a thermoplastic polymer well-suited for medical applications due to its heat resistance, chemical stability, high strength, and sterilization compatibility features.

We understand the critical requirements for medical products. That’s why we can work with you to design and manufacture polysulfone parts that meet your exact specifications.

What is Polysulfone (Udel®)?

Polysulfone is a polyether-containing polymeric material highly resistant to heat, chemicals, and solvents. It has good mechanical properties and a high melting point and can be used in various applications, from medical devices to food service components.

Polysulfone material also has excellent chemical resistance and can withstand harsh environments such as caustic cleaning agents or steam sterilization cycles. It is also one of the few polymers that can resist hydrolysis over long periods, making it ideal for use in various fluid-handling systems & medical sterilization.

Polysulfone (Udel®) for medical applications

Polysulfone is ideal for medical applications due to its strength and dimensional stability. It can be used in various medical instruments, including tubing, catheters, and other medical equipment.

Due to its excellent chemical resistance, polysulfone is often used as a protective sheath over electrical wires and cables in medical devices. This helps protect the machines from static electricity or other potential hazards while providing a durable surface that can withstand frequent use.

Another major use of polysulfone in the medical industry is as an implantable material. Due to its high strength-to-weight ratio and biocompatibility, polysulfone can be used for many types of implantable devices, such as corneal lenses.

Our trusted products for the medical industry

National Plastics and Seals is the medical industry’s go-to source for precision machined parts. We understand that reliability and accuracy are of utmost importance when it comes to producing medical components, which is why we only use top-quality materials and guarantee superior results. Aside from Polysulfone (Udel®), we integrate the following materials for medical use.

5% Boron-Filled HDPE

5% Boron-Filled HDPE is quickly becoming a reliable material for medical X-Ray applications. This innovative material eliminates the need for lead as a shielding material. 5% Boron-Filled HDPE is lighter – making it easier to transport, and more cost effective than lead. The 5% Boron Filled HDPE has excellent shielding properties, and its composition makes it an ideal choice for medical applications.

Polyetherimide (Ultem®)

Polyetherimide Ultem® is a unique thermoplastic that has set itself apart from all other materials in the medical industry. The material’s superior performance, durability, and chemical resistance make it ideal for healthcare applications, particularly those requiring temperature stability.

PEEK

PEEK (polyetheretherketone) is a polymer gaining traction in medicine due to its excellent strength and flexibility. It is often used as an alternative to metal implants, such as hip replacements and dental screws. PEEK can be tailored to deliver both structural support and functionality for implants that need to withstand extreme forces or long-term wear and tear.

Its biocompatibility makes it ideal for implantable devices, as it does not cause an immune reaction. PEEK is also less expensive than metal implants, making it a cost-effective option for medical applications.

Top-notch machined parts for the medical industry

When it comes to the medical industry, reliable and durable materials are of utmost importance. We use polysulfone materials and other high-grade performance materials to ensure that your parts are certified and safe for any application.

We understand that performance plays a crucial role in high-quality parts when you collaborate with us. Rest assured they will be designed and engineered to meet your highest standards. Contact us today to learn more about how we can help you.