How Does Heat Shrink Tubing Help Electric Vehicles?

Leave a CommentElectric vehicles (EVs) make up a rapidly-increasing segment of the automotive market. As green technology and environmentally friendly initiatives continue to influence the automotive industry, many large-scale original equipment manufacturers (OEMs) are focusing more exclusively on EV production.

This massive market shift places critical importance on EV batteries. Electric vehicle batteries must be properly encapsulated and secured, using specialized materials that protect from environmental conditions while increasing dielectric strength and reducing flammability. This article will discuss how to heat shrink wrap an EV battery, and the benefits heat shrink tubing delivers.

How to Heat Shrink Wrap a Battery

Heat shrink tubing is an effective method of sealing and protecting electric vehicle batteries. It not only provides protection from weather conditions but short circuits as well. To shrink wrap a battery, you must follow these steps:

Choosing Heat Shrink

While many types of heat shrink are available, a large diameter, thin PVC heat shrink is an effective choice for EV battery applications.

Sizing the Heat Shrink Tubing

Heat shrink is available in rolls and is measured by its expanded inside Diameter (ID) and recovered ID. To calculate the size needed for a given application, the perimeter of the battery must be calculated. Most heat shrink has a shrink ratio of 2:1 and should be less than twice the battery’s size. It’s important to choose a size that will fit snugly on the battery.

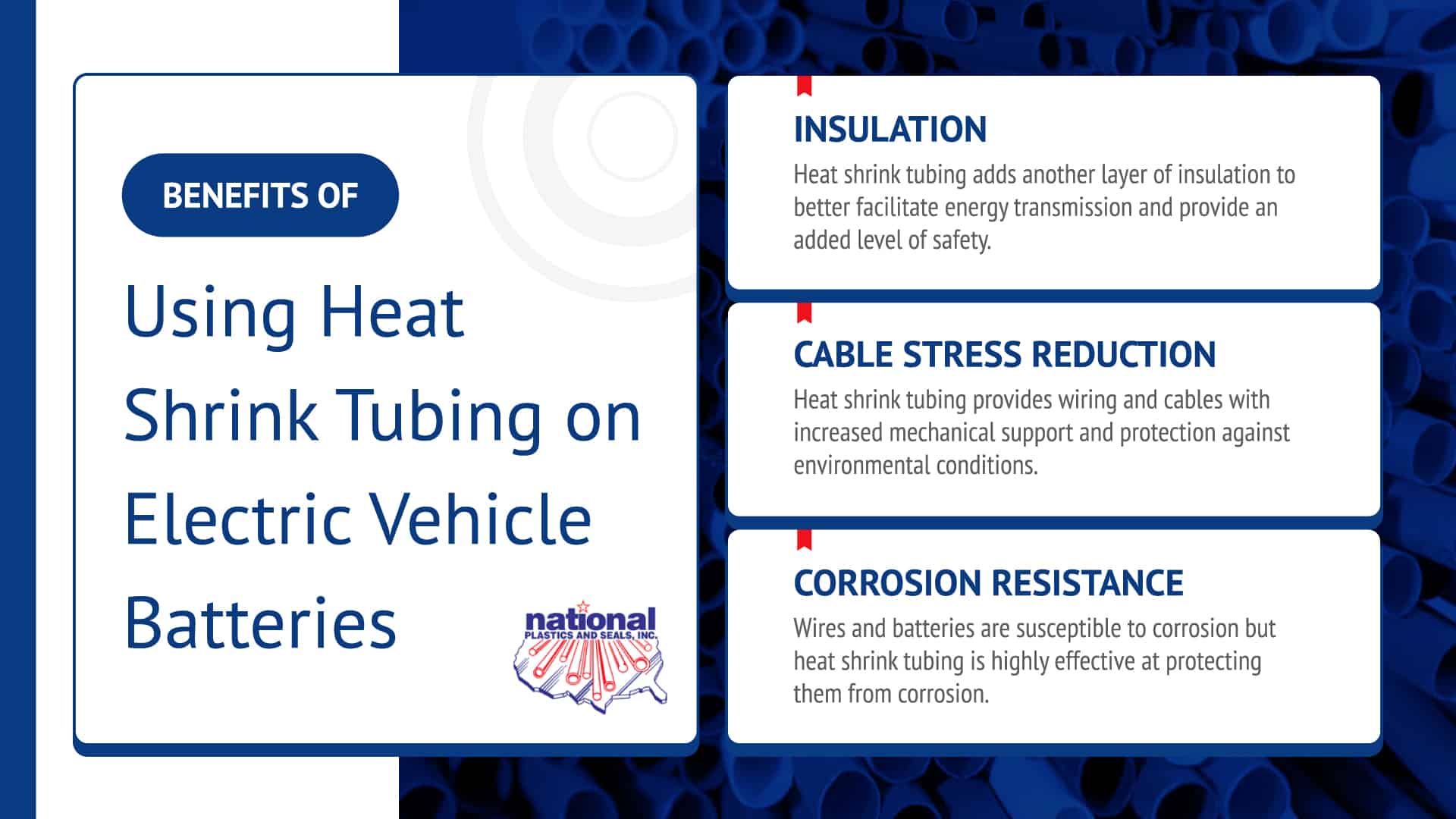

Benefits of Using Heat Shrink Tubing on Electric Vehicle Batteries

Heat shrink tubing delivers many significant benefits for electric vehicle batteries. For example, it provides reliable protection against many types of challenging environmental conditions. Without exposure to factors such as humidity, oils, grease, chemicals, and other substances, the battery along with its wiring and cables can perform optimally for much longer. Other benefits include:

- Insulation. Heat shrink tubing provides an additional layer of non-conductive insulation between the battery and anything that might come into contact with it. Thicker insulation facilitates better energy transmission and adds an additional level of safety.

- Cable stress reduction. Wiring and cables receive increased mechanical support and protection against exposure to environmental conditions when heat shrink tubing is used. Heat shrink also ensures cables aren’t stretched or confined to areas of insufficient space.

- Corrosion resistance. While the metals used in cables and wiring can be made to be corrosion-resistant, insulating them with a reliable material is the only way to ensure they are fully protected from corrosion. Heat shrink tubing is highly effective at protecting batteries and wires from corrosion.

Why Our Clients Choose National Plastics and Seals for Heat Shrink Tubing Electric Vehicle Batteries

National Plastics and Seals has over 30 years of experience delivering heat shrink tubing solutions. We offer a comprehensive selection of heat shrink tubing products, including a wide range of shrink ratios, materials, sizes, and colors.

Value-Added Services

To meet the unique needs of each application, we offer several value-added services, including:

- Cut to length. Utilizing state-of-the-art tube cutting machines, National Plastics and Seals cuts heat shrink tubing to any desired length from spools or 4 ft. sticks.

- Printing and marking. Customer part numbers, serialization, and sequential numbering can be added using the latest heat shrink printing technology.

- Customer requirements. We comply with PPAP, REACH, COC, RoHS, and other material certifications. We can also meet military and major commercial specifications.

National Plastics and Seals supplies heat shrink tubing with inside diameters that range from 3/64 in. to 6 in., and lengths ranging from 4 ft. to 1,000 ft. spools. Heat shrink solutions from National Plastics and Seals meet stringent international specifications and deliver high flexibility even in low-temperature conditions. Our products help protect against punctures, ultraviolet radiation, diesel, petrol, and many other chemicals, which is extremely important for EV batteries. Additionally, the broad selection of color options we carry allows for easy wire color-coding.

National Plastics and Seals for Heat Shrink Tubing Solutions

Batteries used in electric vehicle applications are exposed to many challenging environmental conditions that can be highly damaging. Heat shrink tubing safeguards against these risks and helps ensure a longer and more reliable battery and wire lifespan. As an industry leader in precision fabricated plastic components, National Plastics and Seals delivers highly effective heat shrink tubing solutions that meet even the most stringent specifications. Learn more about our products and services by requesting a quote today.