National Plastics and Seals (NPS) is an industry leader in manufacturing top-quality, custom-designed plastic acrylic displays. Our custom acrylic plastic fabrication products include everything from acrylic barriers, POP displays, and table tents to memorabilia cases, trophies, and brochure holders. We can handle the production of custom display products for a wide range of industries including retail, restaurants, healthcare, schools, and many more.

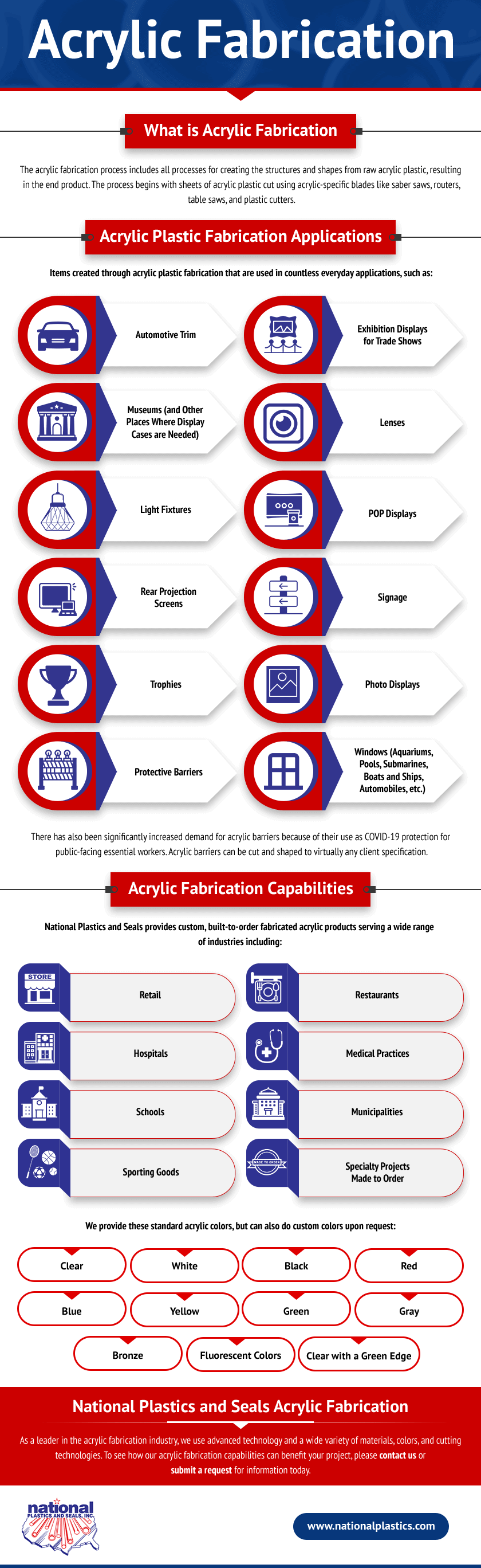

What is Acrylic Fabrication

Shock-proof, light-weight acrylic is a see-through, durable alternative to glass that can be shaped, cut, and transformed into a wide variety of products. Acrylic is often chosen because it does not break as easily as glass, so it performs especially well in situations where glass would not. Submarine windows are a primary example of this, as a thick, clear acrylic window can provide the visibility needed while withstanding the high external operating pressures.

The acrylic fabrication process includes all processes for creating the structures and shapes from raw acrylic plastic, resulting in the end product. The process begins with sheets of acrylic plastic cut using acrylic-specific blades like saber saws, routers, table saws, and plastic cutters. Additional relevant processes may include:

- Heat Bending

- Forming

- Printing

The finished acrylic products achieve a glossy, polished finish through the application of a hydrogen-oxygen torch.

Acrylic Plastic Fabrication Applications

Items created through acrylic plastic fabrication that are used in countless everyday applications, such as:

- Automotive trim

- Exhibition displays for trade shows

- Museums (and other places where display cases are needed)

- Lenses

- Light fixtures

- POP displays

- Rear projection screens

- Signage

- Trophies

- Photo displays

- Protective barriers

- Windows (aquariums, pools, submarines, boats and ships, automobiles, etc.)

There has also been significantly increased demand for acrylic barriers because of their use as COVID-19 protection for public-facing essential workers. Acrylic barriers can be cut and shaped to virtually any client specifications.

Acrylic Fabrication Capabilities

As an industry leader in acrylic fabrication, National Plastics and Seals can provide custom, built-to-order fabricated acrylic products to their exact specifications, in a wide variety of shapes, colors, and thicknesses. We serve a wide range of industries including:

- Retail

- Restaurants

- Hospitals

- Medical practices

- Schools

- Municipalities

- Sporting goods

- Specialty projects made to order

We can handle low- or high-volume production runs and are able to work with designs provided in AutoCAD, Corel Draw, Enroute, and PDF formats. We provide these standard acrylic colors, but can also do custom colors upon request:

- Clear

- White

- Black

- Red

- Blue

- Yellow

- Green

- Gray

- Bronze

- Fluorescent colors

- Clear with a green edge (so it looks like a pane of glass)

National Plastics and Seals Acrylic Fabrication

As a leader in the acrylic fabrication industry, we use advanced technology and a wide variety of materials, colors, and cutting technologies. To see how our acrylic fabrication capabilities can benefit your project, please contact us or submit a request for information today.

- General Design & Manufacturing Capabilities

- Acrylic Displays

Design - Prototype

Production

- Acrylic Displays

- Acrylic Display Types

- POP Displays

Table Tents

Picture Frames

Brochure Holders - Bulk Food Bins

Shelves / Risers

Memorabilia Cases

- POP Displays

- Design & Prototype Capabilities

- CAD Design

- Full Size Prototype

- Materials Used

- Acrylic

Polycarbonate

Sintra

Polyethylene Terephthalate (PETG) - Polypropylene

High Impact Polystyrene (HIPS)

PVC

Others

- Acrylic

- Available Colors

- White

Clear

Red

Blue

Yellow

Green - Black

Bronze

Gray

Fluorescent

Green Edge (looks like glass)

Custom Colors Available Upon Request

- White

- Joining Methods

- Solvent Bonding

Tape - Hot Air Welding

- Solvent Bonding

- Finishes

- Flame Polishing

- Silk Screening

- Features/Characteristics

- Chemical Resistant

Impact Resistant - UV Resistant

- Chemical Resistant

- Additional Capabilities

- Fulfillment

Build-to-Order - Drop Shipping

Custom Packaging

- Fulfillment

- Production Volume

Small Run to Large Quantity Runs

- Typical Lead Times Available

Available Upon Request

- Length

Up to 8 ft.

- Width

Up to 5 ft.

- Thickness

Up to 2 in.

- Laser Engraving

Up to 18 x 24 in.

- Laser Engraving Thickness

Up to 3/8 in.

- Industries Served

- Restaurants

Retail Stores

Hospitals - Sporting Goods

Specialty Custom Projects

- Restaurants

- File Formats Accepted

- AutoCAD

Corel Draw

Enroute - Images

PDF

- AutoCAD

Learn More

National Plastics and Seals can fulfill a wide range of order types, from single prototypes and low-volume orders to high-volume and blanket orders. Lead times depend on the request but can be quoted on a job-by-job basis, and emergency and rush services are available.

As an ISO 9001 company who practices lean manufacturing, and Kaizen/5S principles we’re committed to quality in everything we do. We have the ability to meet numerous industry standards, including those set forth by the American Society of Mechanical Engineers, U.S. Department of Transportation, the Federal Aviation Administration, the Food and Drug Administration, and the Society of Automotive Engineers.

To learn more about our heat-shrink tubing and insulation sleeves and discuss how we can help with your unique application, reach out to the team today.