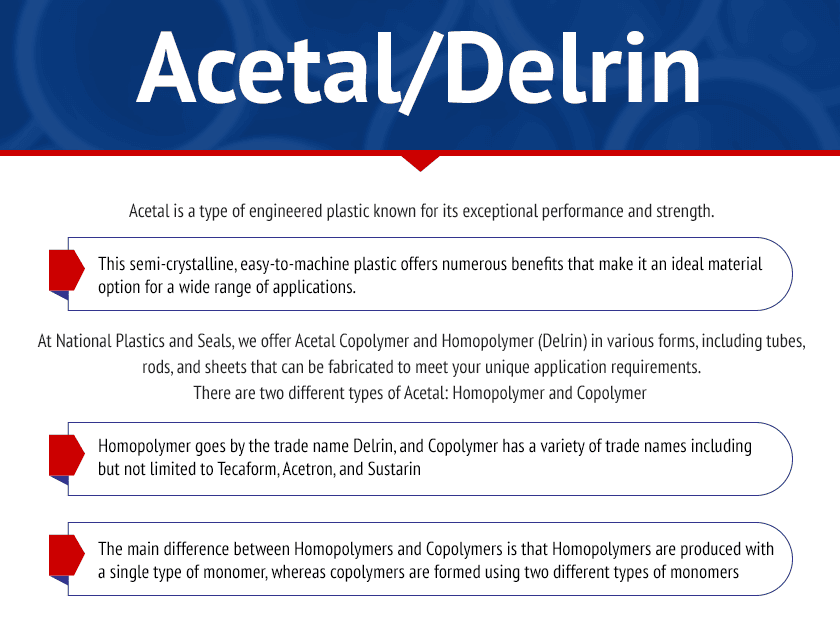

Acetal is a type of engineered plastic known for its exceptional performance and strength. This semi-crystalline, easy-to-machine plastic offers numerous benefits that make it an ideal material option for a wide range of applications.

At National Plastics and Seals, we offer Acetal Copolymer and Homopolymer (Delrin) in various forms, including tubes, rods, and sheets and can be fabricated to meet your unique application requirements.

- Types

-

- Extruded

- Compression Molded

- Material Form:

- Sheet

- Rod

- Tube

- Specialty Grades:

- PTFE filled (Delrin AF)

- Glass Filled

- Metal Detectable

- Medical Grade

- Color:

- Natural

- Black

- Blue

- Primary Colors available in medical Grade

- Sizing:

- Sheet Thickness: .125” to 10”

- Rod Diameter: Starts at 1/8” to 20″

- Tube: 1/8” ID to 10” OD with various wall thicknesses

- Custom sizes available upon request, please call for details

- In house fab services:

-

- Cut to size

- CNC Milling

- CNC Turning

- CNC Routing

- Screw Machining

- Applications:

- Food Conveyor and Packaging parts

- Pumps, Valves and Fitting

- Impellers

- Cams

- Bushings/Bearings

- Star Wheels

There are two different types of Acetal: Homopolymer and Copolymer. Homopolymer goes by the trade name Delrin, and Copolymer has a variety of trade names including but not limited to Tecaform, Acetron, and Sustarin. The main difference between Homopolymers and Copolymers is that Homopolymers are produced with a single type of monomer, whereas copolymers are formed using two different types of monomers.

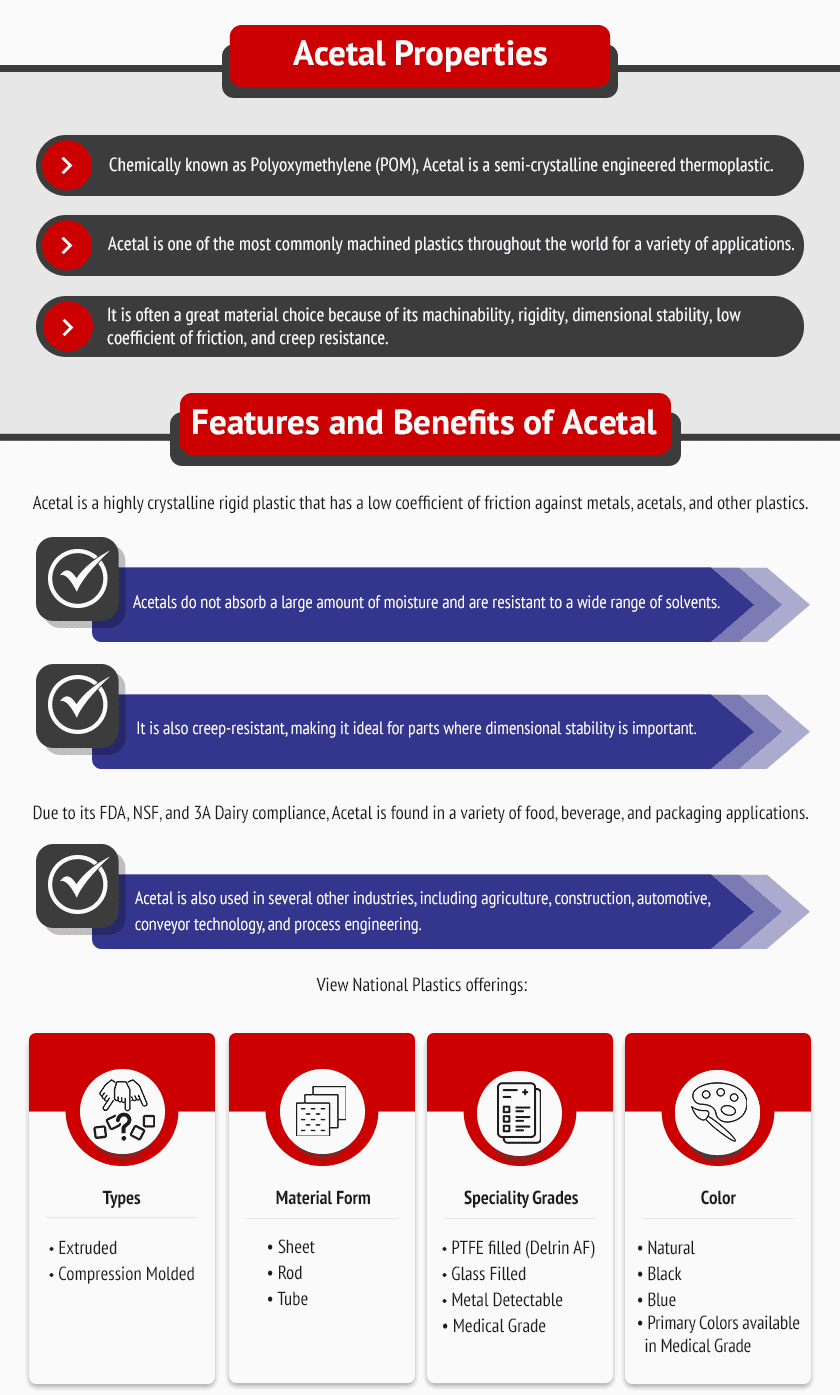

Acetal Properties

Chemically known as Polyoxymethylene (POM), Acetal is a semi-crystalline engineered thermoplastic. Acetal is one of the most commonly machined plastics throughout the world for a variety of applications. It is often a great material choice because of its machinability, rigidity, dimensional stability, low coefficient of friction, and creep resistance.

Features and Benefits of Acetal

Acetal is a highly crystalline rigid plastic that has a low coefficient of friction against metals, acetals, and other plastics. Acetals do not absorb a large amount of moisture and are resistant to a wide range of solvents. It is also creep-resistant, making it ideal for parts where dimensional stability is important.

Due to its FDA, NSF, and 3A Dairy compliance, Acetal is found in a variety of food, beverage, and packaging applications. Acetal is also used in several other industries, including agriculture, construction, automotive, conveyor technology, and process engineering.

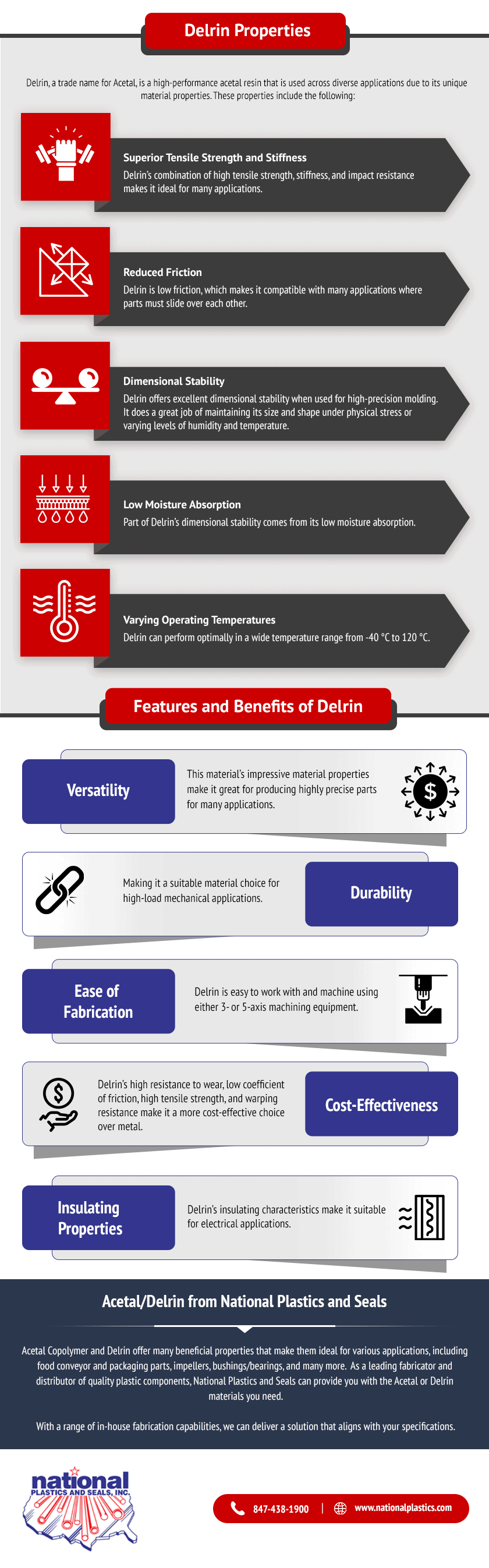

Delrin Properties

Delrin, a trade name for Acetal, is a high-performance acetal resin that is used across diverse applications due to its unique material properties. These properties include the following:

- Superior Tensile Strength and Stiffness. Delrin’s combination of high tensile strength, stiffness, and impact resistance makes it ideal for many applications.

- Reduced Friction. Delrin is low friction, which makes it compatible with many applications where parts must slide over each other.

- Dimensional Stability. Delrin offers excellent dimensional stability when used for high-precision molding. It does a great job of maintaining its size and shape under physical stress or varying levels of humidity and temperature.

- Low Moisture Absorption. Part of Delrin’s dimensional stability comes from its low moisture absorption.

- Varying Operating Temperatures. Delrin can perform optimally in a wide temperature range from -40 °C to 120 °C.

Features and Benefits of Delrin

Key features and benefits of Delrin include:

- Versatility. This material’s impressive material properties make it great for producing highly precise parts for many applications.

- Durability. making it a suitable material choice for high-load mechanical applications.

- Ease of Fabrication. Delrin is easy to work with and machine using either 3- or 5-axis machining equipment.

- Cost-Effectiveness. Delrin’s high resistance to wear, low coefficient of friction, high tensile strength, and warping resistance make it a more cost-effective choice over metal.

- Insulating Properties. Delrin’s insulating characteristics make it suitable for electrical applications.

Acetal/Delrin from National Plastics and Seals

Acetal Copolymer and Delrin offer many beneficial properties that make them ideal for various applications, including food conveyor and packaging parts, impellers, bushings/bearings, and many more. As a leading fabricator and distributor of quality plastic components, National Plastics and Seals can provide you with the Acetal or Delrin materials you need. With a range of in-house fabrication capabilities, we can deliver a solution that aligns with your specifications.

For more information about how Acetal and Delrin can benefit your plastic application, contact the experts at National Plastics and Seals today.