Heat Shrink Tubing | Insulation Sleeving

To provide protection from wear and tear in various environments, applications often use heat shrink tubing and insulation sleeving solutions.

Heat shrink tubing offers mechanical protection, electrical insulation, strain relief, and environmental sealing for connector-to-cable transitions, back-end connector sealing, stranded and solid wire conductors, terminals, and other applications. Heat shrink tubing allows for fast and easy installation due to its ability to conform to the shape and size of the underlying substrate when heated. Insulation sleeving is a popular type of tubing that many facilities use for insulating cabling and wire.

At National Plastics and Seals, we offer top-quality heat shrink tubing and insulation sleeving products for many applications. They’re available in a range of sizes, materials, and colors.

Applications for Insulation Sleeving

Multiple applications rely on insulation sleeving for different types of electronic components, wiring, and cables. Common applications for insulation sleeving include:

- Insulation for connections and wire terminations

- Insulation for electrical wiring with motors, alternators, and generators

- High voltage applications

- Primary insulation for high-temperature electrical equipment appliances

- Insulation for domestic appliances

Why Use Heat Shrink Tubing?

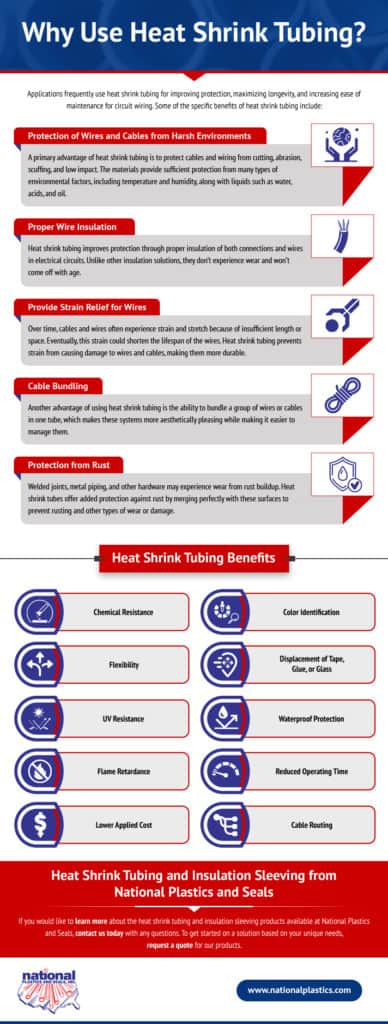

Applications frequently use heat shrink tubing for improving protection, maximizing longevity, and increasing ease of maintenance for circuit wiring. Some of the specific benefits of heat shrink tubing include:

Protection of Wires and Cables from Harsh Environments

A primary advantage of heat shrink tubing is to protect cables and wiring from cutting, abrasion, scuffing, and low impact. The materials provide sufficient protection from many types of environmental factors, including temperature and humidity, along with liquids such as water, acids, and oil.

Proper Wire Insulation

Heat shrink tubing improves protection through proper insulation of both connections and wires in electrical circuits. Unlike other insulation solutions, they don’t experience wear and won’t come off with age.

Provide Strain Relief for Wires

Over time, cables and wires often experience strain and stretch because of insufficient length or space. Eventually, this strain could shorten the lifespan of the wires. Heat shrink tubing prevents strain from causing damage to wires and cables, making them more durable.

Cable Bundling

Another advantage of using heat shrink tubing is the ability to bundle a group of wires or cables in one tube, which makes these systems more aesthetically pleasing while making it easier to manage them.

Protection from Rust

Welded joints, metal piping, and other hardware may experience wear from rust buildup. Heat shrink tubes offer added protection against rust by merging perfectly with these surfaces to prevent rusting and other types of wear or damage.

In addition to these, heat shrink tubing offers a number of other benefits, such as:

- Chemical resistance

- Color identification

- Flexibility

- Displacement of tape, glue, or glass

- UV resistance

- Waterproof protection

- Flame retardance

- Reduced operating time

- Lower applied cost

- Cable routing

Heat Shrink Tubing and Insulation Sleeving from National Plastics and Seals

National Plastics and Seals is a leading supplier of many types of precision machined and fabricated plastic parts. We also distribute a range of products, including heat shrink tubing and rubber products, as well as plastic sheet, rod, and tube profiles. We are ISO 9001:2015-certified and work to provide the highest quality products with on-time delivery.

If you would like to learn more about the heat shrink tubing and insulation sleeving products available at National Plastics and Seals, contact us today with any questions. To get started on a solution based on your unique needs, request a quote for our products.